You’re not the only one singing the blues about delays in construction and remodeling projects. Albert and Christina Cummings have owned the land for their Berkshire Mountains custom home since 2007 and have been eager to begin building their home, dubbed the “House That Blues Built” in honor of Cummings’ career as a blues guitarist, for at least a couple of years. The 18-acre  Massachusetts property includes a pond and (thankfully) plenty of space to store materials during the slow process of getting permits and supplies for construction to begin.

Massachusetts property includes a pond and (thankfully) plenty of space to store materials during the slow process of getting permits and supplies for construction to begin.

“We finally got our permits to start building late last year, but the permits were delayed for months,” says Albert, a fourth generation custom homebuilder. “It’s been extremely frustrating because the issue is just that so many people are not working right now and that slows everything down for people who own businesses.”

READ MORE: The Value of Proper Building Materials Storage

Cummings was persistent in communicating with the permit office to push through the bottleneck and eventually succeeded. The next challenge he faces, along with every builder in the country, is gathering the supplies he needs to build his place.

Keeping materials covered on jobsites will help mitigate risks from inclimate weather

Even a bad situation can be made worse

“I’m actually extremely lucky compared to most builders because I just finished a four-and-a-half-year long remodeling project on a 23,000-square-foot home and for my next project we’ll be demoing a place for a couple of months at least,” Albert says. “Normally I’m ordering $100,000 a month in supplies, but right now I’m ordering much less. For our house, we’re fortunate to have the support of the sponsors who are helping us line up a lot of the materials we need.”

For the House that Blues Built, Cummings has ordered some materials far in advance of when he expects to need them because suppliers have said they don’t know what availability or prices will be like in the spring.

“Despite ordering materials in advance, we had our roof joists well before there were walls to put them on,” Albert explains. “Luckily we’ve got enough land where we can store materials and a forklift to move things around as we need them.”

The Cummings are well into construction now, but it wasn’t without proactive problem solving.

Keeping lumber elevated will help protect it from moisture damage

“Starting a house now on an optimistic whim that everything will be better later is very scary for most builders right now,” he says.

Buying local may avoid some delays99 One thing to be aware of, says Albert, is that American-made products are not getting held up at the ports the way internationally produced goods are.

“That’s something to think about for the future,” he says. “If there’s a way to buy something produced in America, that’s the better option now.”

Cummings recommends ordering every item ahead of time as much as possible, even if that means storing materials for months until they’re needed.

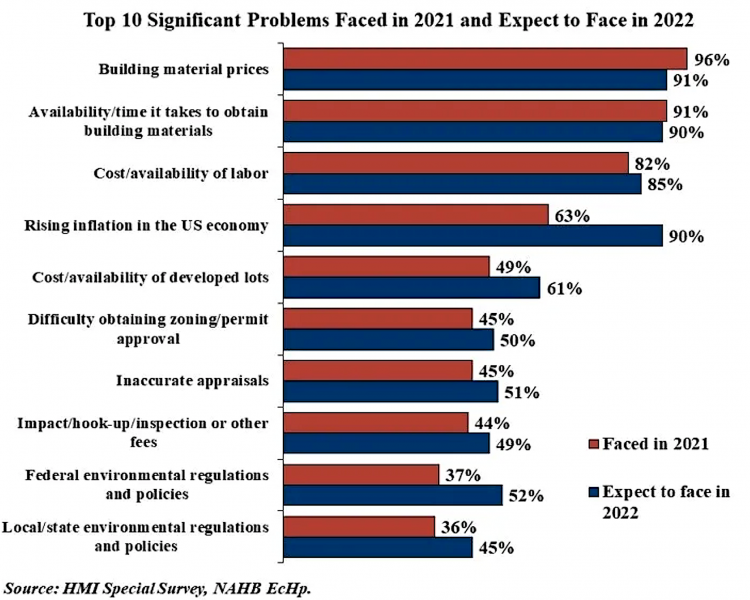

A report from the US Department of Housing and Urban Development and the US Census Bureau found that supply chain problems are having major impacts on construction delays, contributing to the 4.1% decline in overall housing starts recorded in January.

If you don’t have storage space, consider getting some

“But the bottom line for most builders is that it’s hard to schedule deliveries unless you have storage space,” Albert says. “You also worry that you’re paying too much and that prices may drop at some point. But at least you have the materials in place to be able to build something.”

While Cummings says he’s in the luxurious position of having the assistance of sponsors, he recommends that every builder do as they always do: buy what’s best in terms of quality and the clients’ budget as soon as possible. Just be prepared to store everything until it’s needed.

Add new comment