Volatility is the name of the game for the construction industry these days. As project managers contend with changing variables—from material prices to worker availability—the one constant they look to is their supply chain. Finding the right partners to deliver the materials and products they need, when they need them is paramount to completing projects on time and on budget.

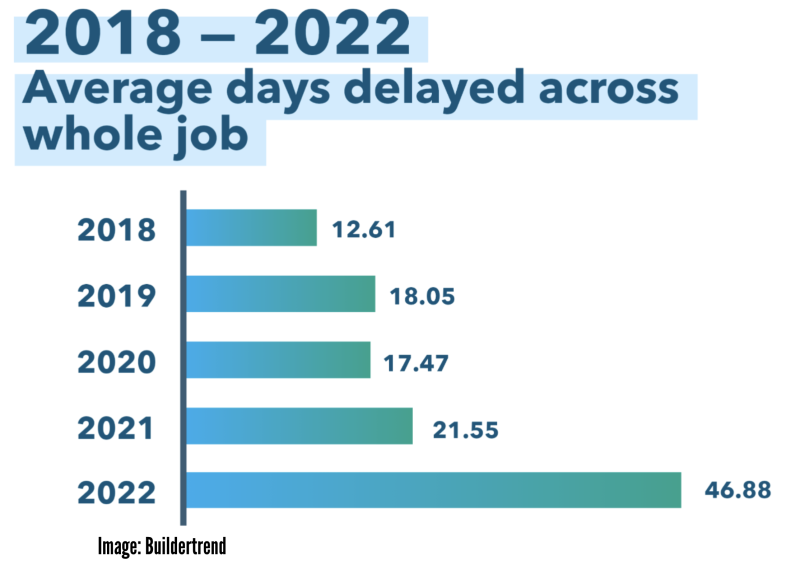

However, supply chain issues that arose during the pandemic persist, including unpredictable material pricing and significant delays. According to Associated Builders and Contractors, despite overall construction input prices being 4.9% lower in June 2023 than in June 2022, prices are still 38% higher than they were at the start of the pandemic. A Buildertrend survey showed that projects were delayed almost 47 days, on average, because of material delays in 2022, an increase of 117% in just a year. And these delays cut into the bottom line.

However, supply chain issues that arose during the pandemic persist, including unpredictable material pricing and significant delays. According to Associated Builders and Contractors, despite overall construction input prices being 4.9% lower in June 2023 than in June 2022, prices are still 38% higher than they were at the start of the pandemic. A Buildertrend survey showed that projects were delayed almost 47 days, on average, because of material delays in 2022, an increase of 117% in just a year. And these delays cut into the bottom line.

The Impact of Last Mile Delivery

While many of the macro challenges in construction are unlikely to disappear in the near term, suppliers that handle “last mile” delivery (that is, to the job site or warehouse) of important building materials can minimize their effects.

Whether materials are ordered well in advance for delivery on a specific date or needed within hours, companies that can consistently provide a positive delivery experience and get supplies to the right construction sites exactly when needed will be rewarded with repeat business and customer loyalty.

To do that effectively, suppliers need a clear understanding of customer expectations and visibility into the potential challenges and hurdles they face. This means they need real-time transparency and insights into the complete order lifecycle, from the moment an order is placed to the moment it’s delivered.

READ MORE: The 2023 State of Supply Chains

Why is this so important? Because when there’s limited visibility into capacity, such as truckload volume, equipment availability, driver schedules, delivery windows, and service times, it hinders the ability to be agile regarding customers’ fluctuating timelines and allocate resources appropriately.

Job sites are fluid environments, with the onus on delivery organizations to ensure orders show up at the right location even when there’s not a street address, which is often the case for construction sites.

Timing is also imperative for ensuring that workers get materials at critical time windows—not to mention ensuring someone is on-site for proof of delivery, meeting installation timelines, and avoiding costly project delays.

These factors are compounded by rising demand for next-day, same-day, and on-demand order fulfillment, which puts more pressure on delivery organizations to have the capability to turn on a dime to meet customer needs. There’s also the need to manage returns when items need to be sent back, including determining who will be handling the return, picking it up, and how.

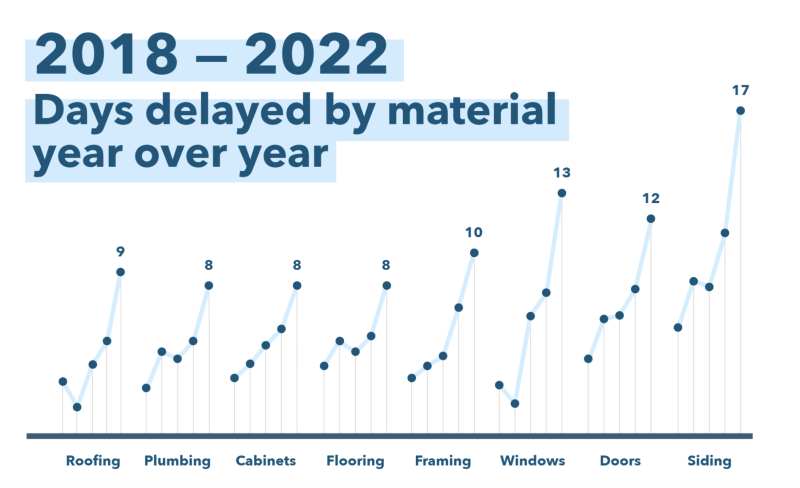

The five product categories most impacted by material delays saw an average 230% increase in delivery times between 2019 and 2022.

Image: Buildertrend

Putting Together the Pieces

Simply put, manual systems are quickly becoming insufficient to meet the rising demands of customers, and many suppliers are adopting more modern systems including comprehensive and fully integrated delivery management platforms. It makes navigating the challenges dramatically easier, giving businesses more robust tools that both boost operational efficiency and provide high-quality service to customers.

Here are three strategies for implementing a modern delivery system:

1. Enable route optimization with AI

Route optimization means different things to different people. But for complex construction supply deliveries, a route optimization platform must be able to:

- Route quickly and scalably, even when last-minute orders require fast turnarounds;

- Provide flexibility for late orders that must be slotted into existing routes;

- Handle routing to job site locations without reliable addresses;

- Account for delivery time differences in the trucks and drivers for specific delivery types;

- Match the right equipment types and driver skills to the right jobs;

- Generate ETAs for orders that are precise, accurate, and can be reliably communicated to customers;

AI needs to be at the heart of these advanced routing platforms. AI-powered routing solutions can learn from previous deliveries, area traffic patterns, and other factors over time to generate highly precise and accurate time estimates.

This approach can be combined with various parameters that are set to show which products must be routed on which types of trucks and which drivers can handle which types of jobs to bring a new, higher degree of flexibility to delivery operations.

AI-powered route optimization—combined with real-time delivery tracking—can also support targeted ETA alerts throughout the delivery, whichcan help ensure those on the job site are ready to accept supplies when they arrive.

2. Enable smart self-scheduling

Building efficient delivery schedules that make the best use of delivery capacity is a challenge under the best conditions. When factoring in construction site time window requests, delivery organizations end up running trucks at half capacity just trying to keep customers happy, which isn't ideal for a delivery company's bottom line.

This is where smart, capacity-aware self-scheduling comes in. The first touchpoint after an order is placed would offer customers a chance to select a delivery slot generated by the routing system that takes into account multiple factors including existing schedules, driver availability, route efficiency, and traffic patterns.

Incorporating these various touchpoints into the customer communication cadence—and doing it automatically—makes customers feel like they’re receiving bespoke, attentive service.

Self-scheduling also addresses the extremely time-sensitive orders resulting from changes at busy job sites. Project managers are able to quickly see if the needed materials can be delivered that day or the next, with guarantees that orders will arrive exactly when they need them.

3. Improve communications with frequent alerts and real-time status updates

Great customer service for building materials delivery comes down to effective communication. To meet expectations, it's important to have a variety of delivery notifications ready to go through the fulfillment process, including:

- Delivery schedule confirmations once an order has been scheduled;

- Route start notifications when the truck has left the warehouse along with a precise ETA for delivery;

- ETA updates when there is a change in the promised delivery time;

- Next stop notifications when the customer should expect the delivery imminently;

- Arrival notifications when an order reaches the site;

- Delivery confirmation once an order is received;

These alerts should be customizable, based on customer preferences, and include company branding. And they should be able to be segmented based on audience, delivery/service type, and more.

Beyond text alerts, live tracking through a customer service portal can set delivery organizations apart. Delivery management technology that enables real-time delivery tracking—not just GPS coordinates, but actual and detailed delivery information—provides maximum visibility that empowers customers with the data they need at their fingertips.

Construction is a highly competitive business, and so is the business of delivering building materials to construction job sites. By transitioning away from manual processes and towards more modern systems for routing, customer communication, and delivery tracking, delivery organizations can provide better service and improve cost efficiency.

The value here is immense, as it plays a central role in helping to keep projects running on time and on budget …which, at the end of the day, is the bottom line.

Satish Natarajan is the co-founder and CEO of DispatchTrack, a global leader in last mile delivery solutions.

Add new comment