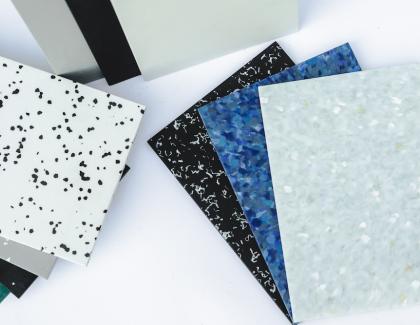

IceStone Solves Problem of Staining on Concrete countertops

Surfacing manufacturer IceStone says it has developed the solution to the once insolvable problem with stain-prone concrete countertops.

The Brooklyn, N.Y.–based company manufactures its IceStone surfacing from 100 percent recycled glass, Portland cement, and non-toxic pigments. As a concrete-based product, the surfacing required periodic sealing to prevent stains.

"After 15 years of searching for a way to protect IceStone from staining we found the solution,” says IceStone CEO Dal LaMagna says. “IceStone has jumped to the front of the line of the most durable stain and heat resistant countertops on the market. It is not vulnerable to ultra violet light or reactive to rain and can now be used outdoors.”

The achieve these results, the manufacturer now incorporates a permanently treated sealing technology that enhances IceStone, “making it a high-level performing surface,” the company says. IceStone explains that the product has been tested on the toughest staining agents including mustard, coffee, vinegar, black markers, lemons and has withstood all of them.

IceStone is now UV protected, has superior stain resistance, more heat resistant than quartz and natural stone, and can be installed outdoors, the company adds. In addition, IceStone will no longer require yearly maintenance and will save fabricators time and money by not having to seal. Once it’s been sealed it won’t need to be sealed ever again.

Add new comment